Your choice of a consultant or contractor can make or break your project – Part 1

In 2000, a water utility which was abstracting raw water from a river experienced an act of God. The intake structure delivering it to an adjacent water treatment plant was washed away by floating vegetation carried by flood waters. This meant that the plant could not receive any raw water. As a result, the town and its inhabitants had to find alternative sources of water. Water is life. You can imagine how many journalists dashed to the scene to capture the events on that fateful day.

You can imagine how many journalists dashed to the scene to capture the events on that fateful day

In order to restore water supply, the water utility assembled an emergency team of experienced electromechanical experts to find a temporary solution. A couple of months after the rescue act had been completed, a project to provide a more sustainable solution was birthed.

In this article, we will profile Daniel’s personal experience as an engineer attached to this project; right from its inception to pre-commissioning. As we go along, we shall appreciate the decisions which were taken by Daniel’s employer, the challenges encountered by the project implementation team, how they overcame these challenges and the lessons learnt.

You must have engaged a design and supervision consultant?

Yes, we did. The consultant was recruited in June 2002. Besides the obvious task of designing a new intake structure to provide raw water for a 25-year design horizon, the consultant was also required to;

- Determine whether the capacity of the existing water treatment plant, fed by the new intake would be sufficient to supply the new consumers who were proposed to be added on to the existing water supply grid.

- Determine whether the flow in the river was sufficient to meet the water demand for a 25-year design horizon.

- Basing on the findings in (i) and (ii) above, the consultant was required to produce a detailed design for the new intake structure and to produce tender documents for construction works.

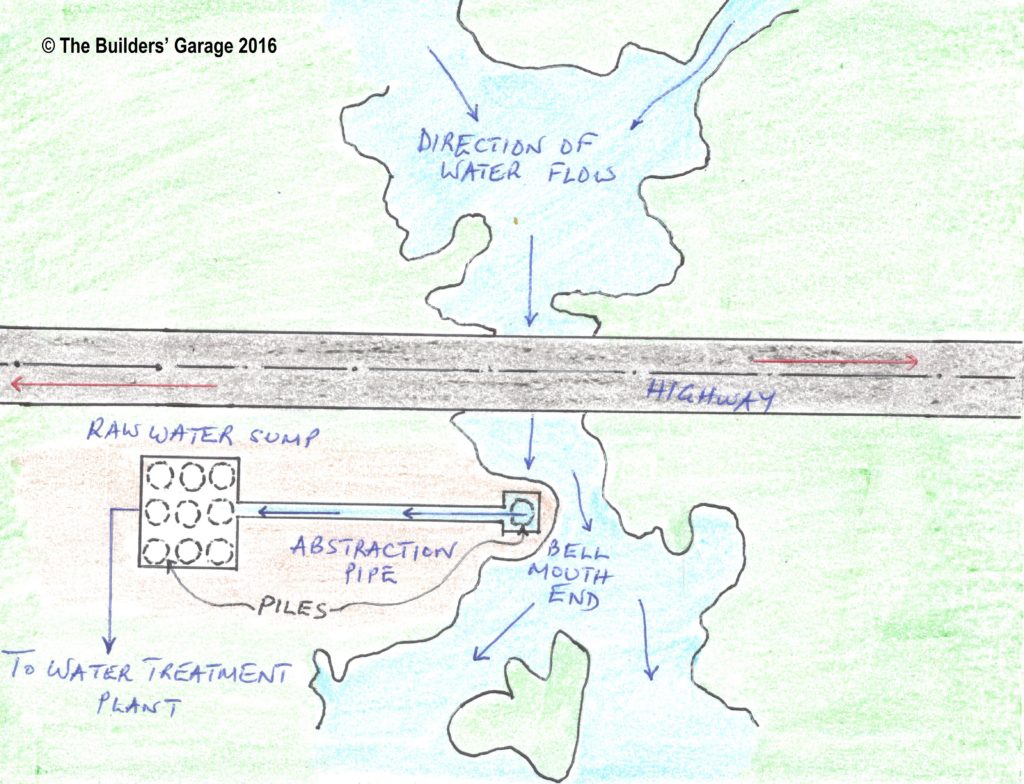

The findings of the feasibility and detailed design study revealed that the water treatment plant had sufficient capacity to meet the 25-year water demand. After the feasibility study and detailed design had been approved by the client, the production of tender documents commenced and was completed in March 2003. The major scope of construction work (a simple sketch is shown in figure 1) involved the construction of a water collection sump and a raw water abstraction main to collect raw water from the middle of the river.

The major scope of construction work (a simple sketch is shown in figure 1) involved the construction of a water collection sump and a raw water abstraction main to collect raw water from the middle of the river

Figure 1: Plan view of the construction site showing the major scope of work

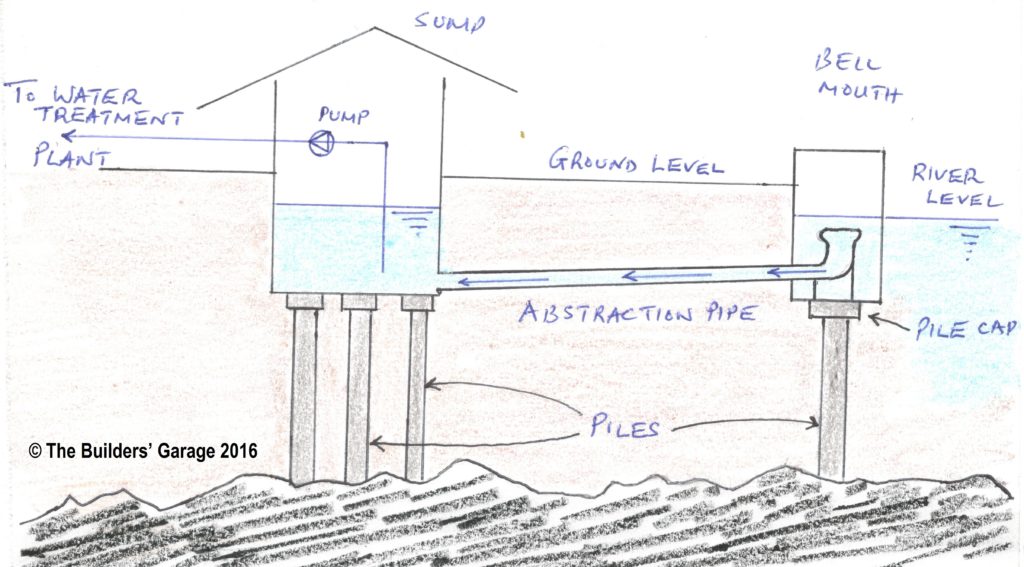

The water sump was designed to rest on 9 bored piles while the bell mouth was designed to rest on one pile. The consultant arrived at an engineering estimate of approximately US$ 1.25m for the construction works. The work was to be funded entirely by the client.

Figure 2: A descriptive elevation of the water sump and the bell mouth supported on piles

Figure 2: A descriptive elevation of the water sump and the bell mouth supported on piles

Now, you had to find a contractor?

Yes, but he had to be a specialised contractor because we had envisaged that the construction works were bound to be abit complex.

The tender for the construction works was announced in the first quarter of 2004. In the tender, we were looking for a specialised contractor with experience in civil and electromechanical works of a similar nature. In particular, it was anticipated that piling would be required to support most of the main structures (the water sump and the bell mouth). This piling, along with most of the civil works was required to take place in a confined space (with limited room for the movement of machinery and equipment) and alongside a flood-prone river with huge volumes of water constantly moving at the edges of the construction site.

The pre-bid meeting was attended by only two construction companies. During the weeks prior to the final submission date of the tenders, we observed that there was very little response to the tender. In order to allow more contractors to express interest in bidding for the construction works, the date of bid submission was extended for an additional 4 weeks. Within this period a number of other firms expressed interest in bidding for the job. However, on the final date of bid submission only three construction companies submitted their bids. Their prices were as follows;

- Bidder A – US$ 2.5m

- Bidder B – US$ 1.6m

- Bidder C – US$ 2.0m

We noted that all the bid prices at submission were higher than the engineering estimate. We were also very uncomfortable with these companies because they seemed new to the water sector and had not worked with us or any other reputable utility before. We developed cold feet.

We noted that all the prices at bid submission were higher than the engineering estimate. We were also very uncomfortable with these companies because they seemed new to the water sector and had not worked with us or any other reputable utility before. We developed cold feet

At some point, a decision had to be taken whether to proceed with the evaluation of the bids or retender and risk losing more time. It eventually dawned on us that we had not packaged the works well enough to make them attractive for reputable companies to express interest. Even if we had decided to retender we would still have received a poor response. It was also unlikely that the reputable companies we were seeking would give us a competitive price. We proceeded to evaluate the bids.

It eventually dawned on us that we had not packaged the works well enough to make it attractive for reputable companies to express interest. Even if we had decided to retender we would still have received a poor response. It was also unlikely that the reputable companies we were seeking would give us a competitive price

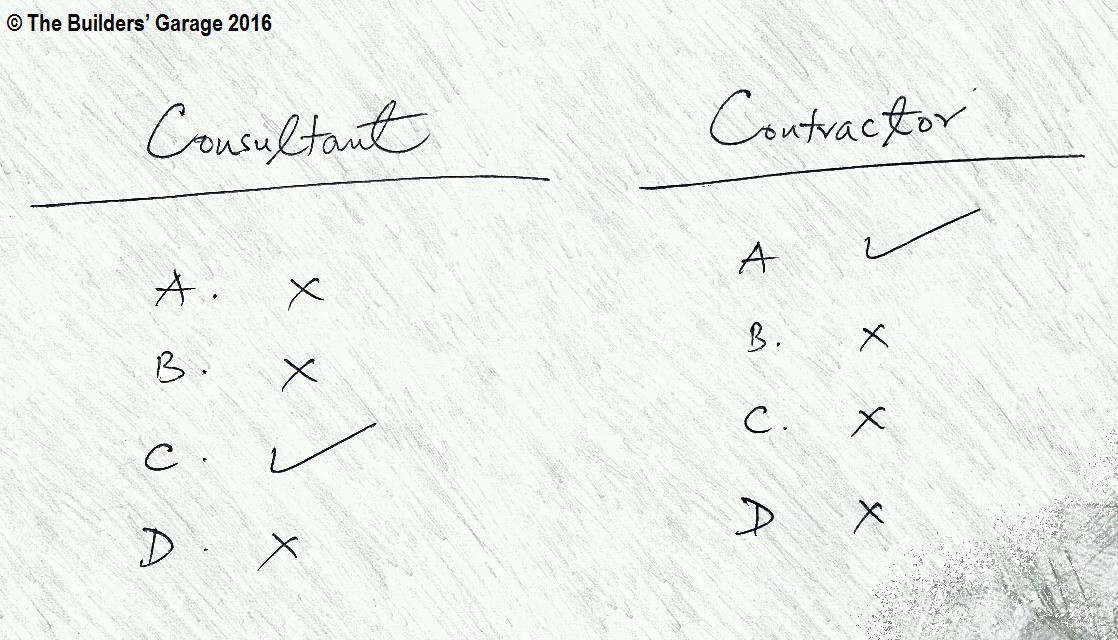

A – The evaluation of bids

During the evaluation of bids, we realised that the lower priced bidders did not demonstrate sufficient technical competence. On the other hand, the higher priced bidder had done some water related works but these were not of similar scope and complexity. However, the bidder demonstrated his willingness to carry out the piling works with a specialised subcontractor. We considered the piling works to be very critical to the success of the project and would not proceed with contract award unless we were absolutely sure that the subcontractor would be able to do the piling.

We considered the piling works to be very critical to the success of the project and we would not proceed with contract award unless we were absolutely sure that the subcontractor would be able to do the piling

The evaluation team proceeded to carry out due diligence on the piling subcontractor to investigate whether the company was capable of executing the piling works, and whether they had agreed to associate with the main contractor as a subcontractor. The due diligence was very successful.

In their detailed design and tender documents, the consultant had proposed the use of a cofferdam to secure the entire site to protect the construction works from the flood-prone river. A provision was made in the bill of quantities for the contractor to price this work method. Theoretically, the use of a cofferdam to secure the construction site from the flood-prone river seemed a workable method but it turned out to be the highlight of my experience on this project.

I will tell you why.

B – The challenges encountered during construction

Construction works commenced in May 2004 and were to be completed in February 2005. The contractor’s first task was to clear the site and create a platform for the movement of equipment and personnel. Thereafter he commenced the piling works which were done in time and they all passed the integrity test.

Figure 3: Piling works at the bell mouth end

Figure 3: Piling works at the bell mouth end

In order to do the marine works, the contractor was required to build a coffer dam. It turns out that the cofferdam would not work because of the limited working space available. The main construction site was located in a very confined space. Also, the rate of seepage of river water into the construction area was too high.

While the contractor was having sleepless nights trying to find a better work method to execute the works, the supervising consultant could not provide a workable solution. It later occurred to me that one of the reasons that the engineering estimate was lower than the contractors’ prices at bid submission is because the design consultant might not have had sufficient experience to provide a realistic engineering estimate for such a specialised job. We were frustrated and I was personally fed up.

We were frustrated and I was personally fed up

The contractor was given an opportunity to propose a new work method since the coffer dam had failed to work. An 8 months’ addendum to the construction contract was processed. This was intended to give the contractor sufficient time to implement his new work method and to allow the client to utilise the available contingency within the contract to pay for the change in the work method.

Daniel, it appears that your consultant was on holiday?

Cyrus, we got a raw deal with the consultant and we (the client) were partly to blame. In the first case, the consultant was guilty of lacking sufficient experience to guide and assist the contractor. At the same time the consultant’s experts were not spending sufficient time on site because we did not fix the minimum time inputs for certain key experts when the consultant was hired. There were times when it appeared that I was working like the consultant.

Continue to Part 2

© The Builders’ Garage 2016. Permission to use this article or quotations from it is granted subject to appropriate credit being given to thebuildersgarage.com as the source.

4 Comments

This is a wonderful experience. Keep it up

Jimmy

Thank you. Please share the article with your associates.

This is a pretty interesting case. I have some questions:

1. Was the best evaluated bidder’s combined initial bidding price plus the 8 months addendum price, higher than the total value of the second best evaluated bidder?

2. In the absence of adequate experienced firms in the bidding process, was sole sourcing ever considered provided it was not far from the estimate provided by the consultant who carried out the feasibility study?

3. Was there a performance guarantee so that if the contractor doesn’t deliver the initial milestones the PG could be activated so that the client recovers funds spent for work done that does not meet the agreed milestones or any errors caused by the contractor?

Looking forward to part 2

1. Once you are already in contract with a contractor, the various prices at bid submission might not be relevant anymore because new scenarios have already played out.

2. The tender for the construction works was an open tender – no single sourcing was permitted at the time. In Part 2 of this article, we will see that single sourcing should have been explored from the onset.

3. Yes, there was a performance guarantee. But if a contractor fails or shows signs of failing to perform as required, triggering such contractual clauses might not take you forward. It is usually the last resort. As a project manager your creative thinking should kick in to get the job done.