Beware of the impact of design alterations that arise during project implementation

Every once in a while, I change the look of the home page on my mobile phone device and whenever one of my daughters gets hold of it, she asks me how and why I have made such a change. One day I told her that the change is to make the page look different, and that it does not affect the functioning of the phone at all. Explaining this to her caused my mind to drift away to one of my projects.

I am currently playing a key role in the implementation of two large infrastructure projects, which, just like many projects, are prone to design alterations (changes).

An alteration can be defined as a change that does not affect the basic character or structure of the thing it is applied to. In regard to infrastructure projects, an alteration refers to a change, which shall not necessarily affect the functionality of a system, feature or process.

In this article, I profile my personal experience with design alterations through four questions that I asked myself as the events of one of these projects unfolded. It is my wish that you will appreciate the challenges that I encountered, how they were solved and the lessons I have learnt since.

1.0 Why do design alterations occur?

At one of the project sites; a water treatment plant that had been designed to function with sludge drying beds situated approximately 50 meters away (in a nearby swamp) from the main construction site, was being upgraded. Unfortunately, a detailed geotechnical study for the bed foundations had not been carried out at the detailed design stage.

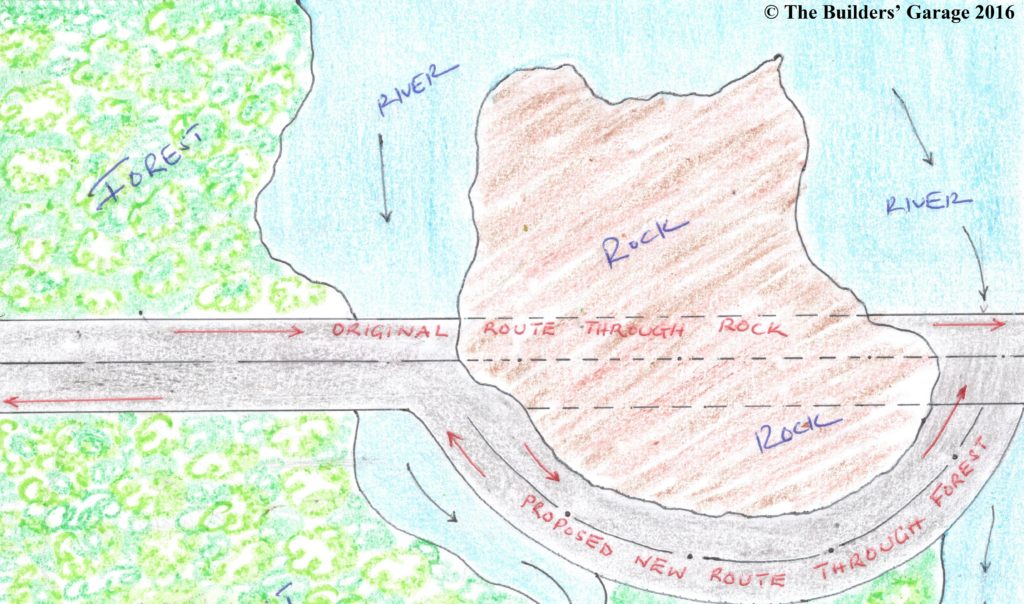

A few weeks after commencement of the construction works, the contractor wrote a letter to the supervising engineer expressing difficulty in accessing the site for the sludge drying beds. In his letter to the engineer, he stated that he was experiencing an unforeseen circumstance. His major concerns were;

- The main point of entry to the site was being used as an access point for large earth moving construction equipment to other parts of the site.

- In order for his equipment to comfortably reach the site for the sludge drying beds, he had to find an alternative access route (different from the main point of entry) requiring him to demolish the property of the people living along this proposed access route and in the peripheral of the swamp.

In his response to the contractor, the consultant said that the scenario which the contractor was facing could not be considered as an unforeseen circumstance and that the contractor should have foreseen that such challenges were bound to arise when he was preparing his technical proposal, and pricing his bills of quantities during the tender period. He was instructed to find a solution to this issue and submit to the engineer an appropriate work methodology for approval.

When this issue came to my notice, I initially thought that I should simply wait for a solution from the contractor, but I was wrong.

When this issue came to my notice, I initially thought that I should simply wait for a solution from the contractor, but I was wrong

On further investigation into the issue, I also realised that the Environmental and Social Impact Assessment (ESIA) report which had been developed by a previous consultant and approved by all the relevant authorities prior to the implementation of construction works, had omitted this scope of work. We were bound to get into serious trouble with construction works at this site.

On further investigation into the issue, I also realised that the Environmental and Social Impact Assessment (ESIA) report which had been developed by a previous consultant and approved by all the relevant authorities prior to the implementation of construction works, had omitted this scope of work. We were bound to get into serious trouble with construction works at this site

2.0 What will a design alteration cost?

I proposed that we consider an alteration to the design in order to circumvent the issues above. At the time, I did not realise how huge a decision this would turn out to be.

My superiors sanctioned a redesign. As soon as the consultant was instructed to carry out the redesign, the contractor was instructed to suspend construction works at this site and to amend his works programme accordingly.

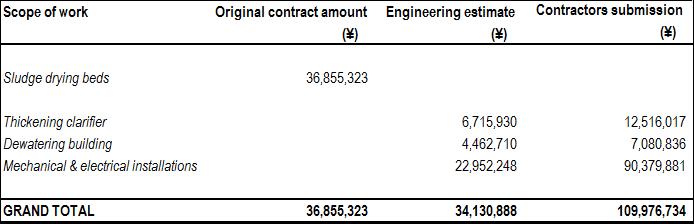

Within approximately three months, the consultant had submitted his redesign to us. His submission comprised a detailed design report, book of drawings and an engineering estimate. After a week of numerous correspondences between the consultant and myself, I approved the redesign especially since it had indicated that there would be cost savings (amounting to ¥ 2,724,435) realised as a result of the design alteration.

The consultant proposed to replace the sludge drying beds with a sludge thickening clarifier, and a filter sludge press. The filter sludge press was to be housed in its own building. These new structures were proposed as alternatives to the sludge drying beds. The new design was to be powered by electromechanical equipment situated in the filter press building.

The consultant redesigned the sludge drying system to fit within the extents of the site which were covered by the existing Environmental and Social Impact Assessment (ESIA) report. He also envisaged that access to construct this system would not be an issue at all since the new structures would be easily accessed through the main gate of the existing water treatment plant. With these amendments, we had sorted out the issues related to the ESIA study and access to the site.

The revised drawings and bill of quantities for the new sludge treatment system were forwarded to the contractor to provide the client with a fresh quotation to carry out the work. The contractor took three months to submit a revised price for the work. On analysis of the contractor’s submission (as indicated in Table 1 below), I realised that the contractor had given us a quotation which was three times the value of the engineer’s estimate.

Table 1: Cost comparison with the original contract amount, engineers estimate and the contractors submission

Now, you will recall the issue related to access of the construction site which the contractor had raised. In some way, I thought that by recommending the design of an easier-to- build alternative system, it would save the project money but I was wrong.

I thought that by recommending the design of an easier-to- build alternative system, it would save the project money but I was wrong

I did not expect the contractor to turn around and submit such an outrageously expensive quote. I was a bit frustrated but I had to prescribe another solution to curtail the contractor’s expectations. At this point we had already gone six months into the project’s construction period with no physical works (related to this scope of work) done.

I did not expect the contractor to turn around and submit such an outrageously expensive quote. I was a bit frustrated but I had to prescribe another solution to curtail the contractor’s expectations. At this point, we had already gone six months into the project’s construction period with no physical works (related to this scope of work) done

3.0 Can alterations be prevented?

This project had about seven key construction sites which were all prone to alterations (changes); most of them insignificant and others requiring the contractor to submit a fresh quote. Therefore, prescribing a solution to the issue that was before me required that I look at the entire project as a whole, since there were other potential variations elsewhere.

I shared my dilemma with my superiors. One of them proposed that the electromechanical works amounting to ¥ 90,379,881 should be eliminated from the scope and tendered out separately. Another of my superiors proposed that the design should be changed once again.

It was finally decided that the sludge water from the water treatment plant should instead be pumped to alternative sludge drying beds which were already under construction at a different site, approximately 2 kilometers away from the water treatment plant. The overall cost for this alteration would cost approximately ¥ 6,268,657; more than 100% less than the contractor’s revised quote of ¥ 109,976,734.

4. What are the lessons learnt?

-

We have recently published an article which could give you an insight into what could happen if you make the wrong choice of a consultant or contractor. In this case the client and engineer played into the hands of the contractor and almost got ‘burnt’. On the other hand, if the contractor had not raised reservations about the nature of work envisaged at the site for the sludge drying beds, my superiors and I might not have thought of a much cheaper alternative. This goes to show that certain design changes can actually result in cost savings but the chances that they result in a cost increase are much higher.

-

As you commence and eventually finalise any detailed design process; leading up to physical construction works, it is very important to seek for a second, third and even fourth opinion on the final detailed design, the work methods being proposed, the estimated costs for construction work and the likely contractors whom you will have on site. With this level of preparation, the chances that you have to do a major variation on site will be minimised.

-

You are not always doing the project a favour by sanctioning a redesign. The contractor and engineer (even though he is a professional) are businessmen. They will most likely take advantage of any loophole to earn an extra coin.

-

Crosscutting issues such as environmental and social issues are crucial in project implementation. The decision to sanction a redesign was taken partly because the existing Environmental and Social Impact Assessment (ESIA) did not cater for the entire construction site.

- Redesigning has a cost to it. Usually the supervising engineer on site needs to be paid to carry out this task. In this case, the engineer did not ask to be paid any extra money because he had designed and located the sludge drying beds in an inappropriate location, and without carrying out a thorough due diligence on the ESIA documents approved prior to commencement of construction works. Time is also lost when a redesign is sanctioned because the engineer and contractor will request for an extension of time with related costs.

5.0 Conclusion

Obviously, my seven-year-old daughter will not understand this story but I hope that you have found it worth your while.

© The Builders’ Garage 2017. Permission to use this article or quotations from it is granted subject to appropriate credit being given to thebuildersgarage.com as the source.

Follow The Builders’ Garage on Facebook , like our page to receive updates and leave us a comment

Follow (connect with) the writer (Cyrus Titus Aomu) on LinkedIn